Improving herd reproduction with wearables

6 min read

Getting cows back in calf sooner helps maintain herd longevity and creates a tighter calving pattern supporting overall herd productivity on farm . Wearables offer a way to automate and improve heat detection, reduce labour, and provide real-time data to support better decision-making. They’re especially useful during busy times of the season when manual heat detection can be inconsistent or missed. Research shows wearables are reliable, but don’t guarantee better in-calf rates.

Many farmers are turning to wearable technology like collars and ear tags to monitor cow behaviour. These insights help detect changes in behaviour that signal oestrus. In 2025, around 1 in 5 dairy farms are using wearables, mostly to help with heat detection, which is one of the eight key factors that influence herd reproductive success . Efficiency gains, especially with labour use, also drive productivity.

Wearable technologies such as neck collars, leg bracelets, or ear tags use sensors to monitor each cow's movement against a baseline (for example, the last seven days and/or a herd average), it then sends alerts when activity rises above the set levels. Many wearables also track rumination, eating, or temperature to enhance heat detection accuracy and identify health issues.

Well performing technology can achieve a level of precision similar to an experienced farm manager, though performance varies between and within systems.

Activity systems are data-rich, requiring some data input, but may also offer other measurements of value e.g. rumination data and grazing time.

Technologies fail, be prepared with a backup if this does occur (e.g. weather event).

Wearables provide consistent data to support reproductive decisions. They complement, not replace, skilled observation and expert input.

Monitor premating heats - Aim for 85% of cows cycling by the start of mating. Wearable technology gives early alerts for cows not cycling, so you can step in sooner . Use this data to identify cows that have had at least one premating heat, who are more fertile and ideal for high-value semen.

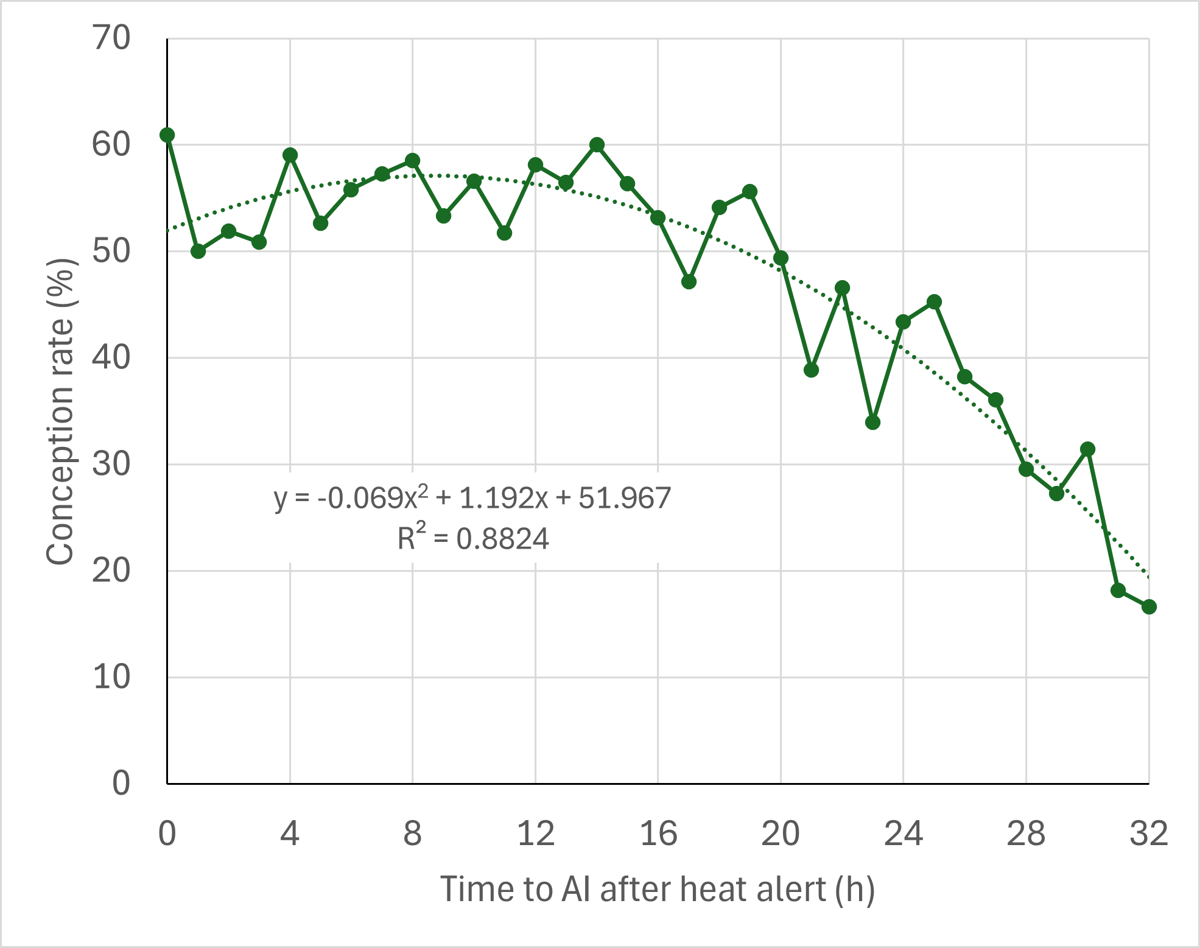

Use heat alerts to time AI - Wearables detect heats 24/7, not just during milking. While the best conception rates happen when cows are inseminated 4–19 hours after a heat alert, the cost of doing AI more than once-daily far outweighs the gains in reproductive performance of the herd. Once-daily AI is okay, and wearable technology is considered reliable. Large-scale studies show there is no need to change AI timing when using sexed semen.

Make strategic mating decisions - Use wearable data to match cows with the right semen type (e.g., sexed semen for fertile cows) and consider oestrus intensity (if available) to guide semen allocation.

Track pregnancy success - Wearables will monitor non-return rates - cows not returning to heat after AI. This gives you an early insight into pregnancy status. However, non-return rate is not a pregnancy diagnosis, as some non-pregnant cows may not display regular heats or silent heats that wearables may not detect. Always confirm pregnancy by scanning at least 32 days after the last insemination before making any culling or management decisions.

Wearable devices are widely used to detect heats, but their sensitivity is lower during the premating period, around 70% . This is expected, as many cows do not show clear signs of oestrus at their first or second ovulation after calving. Despite this, 88% of heat alerts from wearables were accurate, meaning false alerts were relatively low.

Research shows that the timing of artificial insemination (AI) after a heat alert affects conception rates. Studies using wearable devices that monitor cow behaviour continuously have found that:

These findings are based on large datasets from both international and New Zealand herds. While wearables help identify the best AI window, farmers still need to factor in herd routines and technician availability when planning insemination. Doing AI more than once-daily is likely to be impractical and not cost-effective.

Wearables can help predict pregnancy status by identifying whether cows continue to cycle but no system is perfect. It’s recommended to confirm pregnancy with scanning before making culling or wintering decisions. Once a cow is successfully inseminated, she should stop cycling. This can be tracked on-farm using non-return rates (NRR) - cows that don’t return to heat within about 24 days. Wearables continuously monitor oestrus activity, making it easier to track NRR over time compared with manual methods, which often lose accuracy as the season progresses. During this time, there may be management activities occurring that could cause higher activity, which is not a sign of oestrus.

While wearables offer useful data and convenience, they don’t guarantee improved reproductive performance. A recent study found that herds using wearables had no significant change in in-calf rates over the first two years of adoption compared to herds not using wearables. This suggests that wearables support good management and can reduce labour inputs but improved reproductive performance is not guaranteed.

There is emerging evidence that the intensity of oestrus, which some wearables can measure, might influence conception rates. While this link hasn’t yet been confirmed in pasture-based NZ herds, it’s a potential area for future research and could further refine mating strategies.

The performance of all systems depends on the quality and frequency of the data collected, the sophistication of software algorithms (calculations) that generate alerts, and regular maintenance of the associated devices and databases i.e. keeping cow records up to date.

Auto-drafting is a useful option for automating the separation of alerted cows, further reducing manual effort. Achieving and maintaining best performance from the system will require:

Allow time for training and ensure more than one person can understand the software. Be thorough with data quality (e.g. prompt and correct input of cow ID), and with regular data back-ups. Consider having a manual heat detection backup in place (e.g. tail paint) in case of system failure.

Rumination data collected from wearables can support reproductive performance by monitoring cow health and nutrition. It also helps identify transition cow issues as well as detect abnormal cycling or calving behaviour. Read more about how to interpret rumination data.

There have been few comparative studies examining the impact of wearable technologies on herd reproductive performance.

A study in 2024 by DairyNZ has analysed the available data to assess reproductive performance before and after herds adopt wearables compared to a reference group. The analysis used data from 141 self-selected herds with wearables and 1,158 reference herds.

After adopting wearables, farmers extended the duration of their artificial breeding (AB) periods. Some transitioned to all-AB in the first year, eliminating any natural mating periods with bulls. By the second year, most had shifted to all-AB, with the delay most likely to be while they built confidence in the technologies.

The analysis did not provide evidence to support improved reproductive performance. Although herds with wearables demonstrated better reproductive performance, they already showed that prior to adopting the technology. Herds using wearables had higher performance measures, such as 3-week submission and 6-week calving rates, compared to those without wearables, both before and after adopting the technology.

Herds using wearables had lower non-return rates, likely because they tended to have longer AB periods. However, after accounting for mating length, there was no significant difference. When herds were segmented by low or high 3-week submission rate prior to adoption (above or below 80%) there was also no difference in reproductive performance after adopting wearables. Compared with the reference group, results were similar before and after adopting wearables.

In summary, the study showed that if farmers had used wearables to automate their mating, then they had done so without compromising reproductive performance. However, farmers adopting wearables should be conservative when assessing the potential benefits for reproductive performance in investment analyses. While the technology facilitates increased AB mating duration, which could have potential benefits to reproductive performance with accompanying changes to management, these appear not to have been realised by this group of farmers (at least during the first 2 years post-adoption – the period studied).

The investment costs for heat detection can include a cost per cow, fixed costs for electronic identification (EID) readers and computer systems. There are also ongoing maintenance and replacement costs. Payback on investment is highly dependent on upfront costs, and how the new system performs compared with manual heat detection. While there are several potential tangible and intangible benefits to adopting wearables, currently, there is no evidence to suggest that reproductive performance will improve, so farmers should be cautious in factoring in improved reproduction when assessing return on investment.

Consider your reasons for investing in an automated system and evaluate the technologies to understand the trade-offs for you, your team, and your business. If your motivation is to improve reproductive performance through improved heat detection, you first need to be sure that heat detection performance is your key problem.

If your goal is to maintain a high heat detection performance, but with reduced dependence on key skilled people, be mindful that technologies do not replace the need for skilled staff.

Training is needed to use the heat detection system; for entering data, setting alert thresholds and confirming heats, and performing maintenance. Discuss with your technology supplier what training and support will be provided and whether the software is ‘user-friendly’. Skilled handlers will still need to make the final decision on cows selected for artificial insemination.

Prepare a budget using realistic costs and returns so that you know the projected annual costs, the number of years until break-even is reached and the longer-term return on investment.

Organise your budget so you can easily compare costs using the same unit, for example by $/cow/month.

| Example calculation: Comparing cost models for wearables | |

| Payment method | Example calculation |

| $180/device, no subscription Expected 5-year life of device |

$180 ÷ 5 years ÷ 12 months = $3/cow/month |

| $48/device, ongoing subscription $2/cow/month Expected 4-year life of device |

$48 ÷ 4 years ÷ 12 months + $2/cow/month = $3/cow/month |

| No upfront cost, $3/cow/month lease/subscription for device | $3/cow/month |

Ask farmers who currently use an automated system about their experiences. For instance, how they measure the system’s performance objectively and separate from any other changes made in farm management? What changes have they had to make to their daily routines and how much time and skill is required to use the system?

Now’s the perfect time to check in, plan, and set up for a strong season. We’ve pulled together smart tips and tools to help you stay ahead all winter long.

Whether you prefer to read, listen, or download handy guides, we’ve got you covered with trusted tools to support your journey every step of the way.

Put our proven strategies and seasonal tools to work. Boost production, support animal health and watch your profits hum.

Tools that are backed by science, shaped by farmers and made for this season.

That’s Summer Smarts.

Autumn Smarts brings together the research-backed tools that build resilience and boost performance.