Drenching During Milking

3 min read

Drenching is a method you can use during your milking routine to balance your dairy cows' diet and safeguard against metabolic diseases. It's an efficient and reliable way of ensuring each cow receives vital nutrients and minerals like magnesium, zinc, cobalt and selenium. While it's generally easy to implement in herringbone milking systems, it can lengthen milking times and be a bit tricky in rotary dairies. Newer technologies offer alternatives to drenching, such as adding supplements to water or feed. Regardless of the method, it's essential to deliver the nutrients accurately and clean all equipment after each use.

If done correctly the drenching process can be fitted into the normal milking routine with ease, and without any substantial increase in milking times.

Drenching is used to balance the diet of dairy cows and to provide protection against metabolic and other illnesses. Products commonly administered include bloat preventatives, magnesium, zinc to support metabolic processes and trace elements including cobalt and selenium.

As new technologies are developed drenching cows during milking is becoming less common. Alternative technologies include:

Wait until the cow lifts her head, then put the nozzle into the side of the cow’s mouth and releases the trigger. The milker may, but usually does not, need to control the cows’ movement by placing a hand over her muzzle. Drenching should take 3-4sec per cow.

Finish applying the clusters to one side of the herringbone at the yard end and then walk from entry to exit drenching the milked cows as they go.

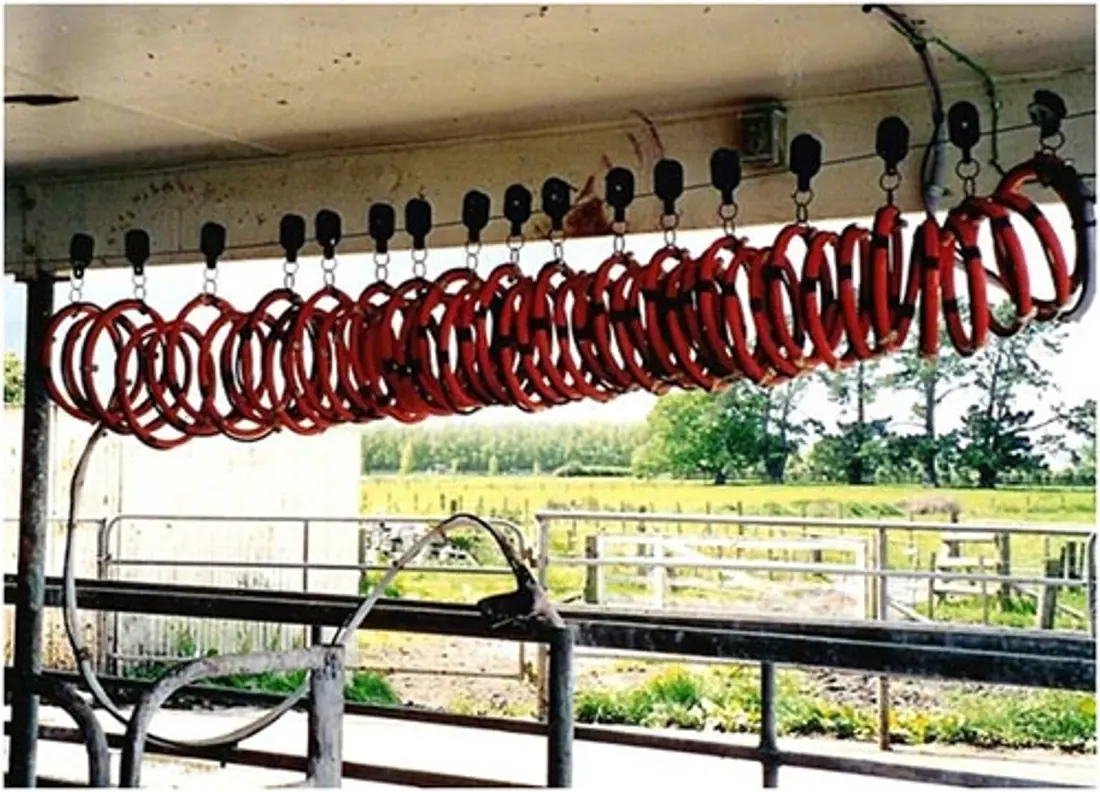

This coiled drench line takes the spray nozzle back to the bail area entry end, ready to be picked up again for the next time this row is drenched.

At the end of a row the drench gun and hose can be flicked back to the yard end again by a coiled spring hose or attached to ‘carriages’ hung on wires on both sides of the bail area and connected to each other by a long cord that returns each gun to its start position automatically.

Coiled drench line

With larger rotaries the drencher usually stays up on a walkway in front of the cows throughout the milking, keeping well away from the entrance to avoid disrupting cow flow on the platform.

The drench hose is suspended from the roof.

A commonly used drenching system, which is commercially available, consists of a 200 litre drum fitted with a long-shafted centrifugal pump, located in a room adjacent to the bail area.

The active ingredient (usually solid) is stored nearby, added to the drum with water and mixed, often continuously, during delivery using a bypass on the delivery pipeline to keep the mix uniform.

Using a hooked nozzle is easier, even when cows are turning their heads away.

To avoid the insoluble solids settling out if left, the mix can be moved continuously in a supply loop to and from the bail area distribution system and drawn off for cows in a measured dose as needed.

A circulating pump, an air compressor and a metering head can be used to accurately measure the required dose. It allows bloat remedy to be kept separate and combined with a mineral mix at the metering head.

Another simple manual system uses timing by the operator to decide the amount required.

Delivery hoses must be cleaned after every milking.

Now’s the perfect time to check in, plan, and set up for a strong season. We’ve pulled together smart tips and tools to help you stay ahead all winter long.

Whether you prefer to read, listen, or download handy guides, we’ve got you covered with trusted tools to support your journey every step of the way.

Put our proven strategies and seasonal tools to work. Boost production, support animal health and watch your profits hum.

Tools that are backed by science, shaped by farmers and made for this season.

That’s Summer Smarts.

Autumn Smarts brings together the research-backed tools that build resilience and boost performance.