Building

5 min read

Building a robust track for dairy farming requires a comprehensive understanding of construction principles and potential problems. This page guides you through the basic steps for constructing a sturdy and efficient track for cow traffic. It highlights the importance of constructing a strong foundation and a suitable surface layer, with emphasis on adequate compaction and drainage. The page also includes considerations for selecting the right materials and offers examples of good and bad track surfaces. By following these guidelines, you'll ensure the track provides a comfortable surface for cows to walk on and remains resilient against wear and tear.

Having a broad understanding of the principles, process and issues that can arise when building a track should help when dealing with contractors.

Here are some basic race construction principles to follow.

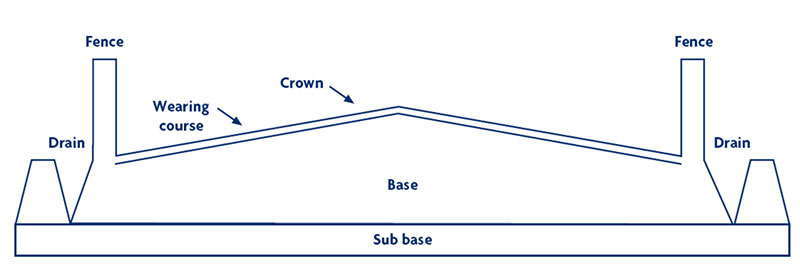

A good track is constructed in layers. A foundation, or base layer, is formed with a surface, or wearing layer, placed on top.

The base layer provides the structural support for the surface layer – if it is weak the surface layer may break up and collapse. If water can penetrate into the base layer it may lose its strength resulting in potholes.

The surface layer has two functions: to provide a comfortable surface for cows to walk on and to shed water to protect the structural integrity of the track.

Each layer should be thoroughly mechanically compacted using vibrating rollers. Loose, open layers have much less strength than well-consolidated ones. Cow traffic does not provide an adequate substitute for mechanical compaction.

Track surfacing and formation. Ensure the camber is between 3-8%, and that the paddock side is fenced off if there are drains beside the track.

Topsoil and grass are not suitable for use in the base layer and should be removed before beginning construction.

The base should be made up of layers, each up to 150 mm deep. After each 150mm layer is laid, it should be firmly compacted before the next is added.

The creation of a satisfactory track surface requires compaction into a hard, smooth, wear resistant layer, with a minimum of particles that can cut or bruise feet.

Good surface layer.

Bad surface layer.

| Examples of track materials | Material properties |

| Rotten rock or volcanic rock |

|

| Limestone |

|

| Crusher dust |

|

To check if a material is appropriate for a top surface, a small sample rock should shatter under the heel of your gumboot when ground against a concrete surface. Trialling small loads of proposed materials will show which are going to work and which are not.

Concrete tracks can be useful in areas of high rainfall as they provide a clean track and reduce mud on udders. However they do require management at the boundary between the concrete and paddocks. A section of lime fines at the intersection can help stones fall off before they get on to the concrete.

A track on a steep slope can mean water runs down the lane before running off the side – resulting in long water scours in the surface layer. Ideally, design tracks to minimise slope, even if it adds distance it will be worthwhile as maintenance issues will be reduced.

Table

Creating table drains at the sides of the track helps to take water away, maintaining track condition. The recommended size for table drains is 300 mm deep and 1 metre wide.

Spur

Spur drains should be installed every 40 to 80 metres to empty the table drains on to paddocks - not to a watercourse. Spur drains should be closer together on steeper slopes.

Lateral

Small lateral drains should be cut into the tracks to allow water to flow away. Not all of the grassy edge should be removed as this is necessary to maintain the structure of the track.

Adequate water table depth is essential to good drainage - ensure the water table is a least 600 mm below the surface to aid the draining of water away from the track.

A water table close to the surface will hinder drainage and may cause the track to become wet, reducing its structural integrity and increasing its chance of collapse.

It may be necessary to build your track above the paddock level in areas with a high water table to ensure drainage occurs.

Now’s the perfect time to check in, plan, and set up for a strong season. We’ve pulled together smart tips and tools to help you stay ahead all winter long.

Whether you prefer to read, listen, or download handy guides, we’ve got you covered with trusted tools to support your journey every step of the way.

Put our proven strategies and seasonal tools to work. Boost production, support animal health and watch your profits hum.

Tools that are backed by science, shaped by farmers and made for this season.

That’s Summer Smarts.

Autumn Smarts brings together the research-backed tools that build resilience and boost performance.