Efficient

5 min read

A well-designed and maintained track for your dairy herd can save time and money, and improve cow welfare. This page details the attributes of a perfect track for cows, including appropriate width based on cow numbers, proper fencing, good paddock access, an optimal surface, and keeping the track as short and distraction-free as possible. By understanding how cows move and using these principles in the design and maintenance of tracks, you can enhance efficiency, decrease incidences of lameness and mastitis, and increase milk production. Maintenance is vital, with a focus on effective drainage and keeping surfaces in top condition.

Well designed, constructed and maintained tracks will save you time and money.

Benefits include:

The perfect track is:

Tracks need to be wide enough for the herd to move without being pressured. Cows with enough space are less likely to push or be pushed.

The width of the track is determined by the numbers of cows you have – or expect to have in future.

Here are some ideal guidelines for track width:

| Cow numbers in mob | Width - metres |

| <120 | 5.0m |

| 120-250 | 5.5m |

| 250-350 | 6.0m |

| 350-450 | 6.5m |

| >450 | Varies depending on the split of the herd |

Make sure cows don't have to walk too far.

The longer the track, the greater the impact on cow comfort and the longer they take to get to the dairy to milk. The energy being used by cows to walk to the dairy can affect milk production.

Ensure there are no distractions. Distractions on the track will lead to cows stopping to take a look, potentially slowing traffic.

This track has no restrictions which will ensure efficient cow flow to and from the shed.

This track has restrictions and distractions which will impede and slow cow flow.

Make sure the track is well fenced from the drains.

Good fencing can prolong the life of a track. It keeps cows out of drains, keeping them out of mud, minimising damage to drains and contamination of waterways.

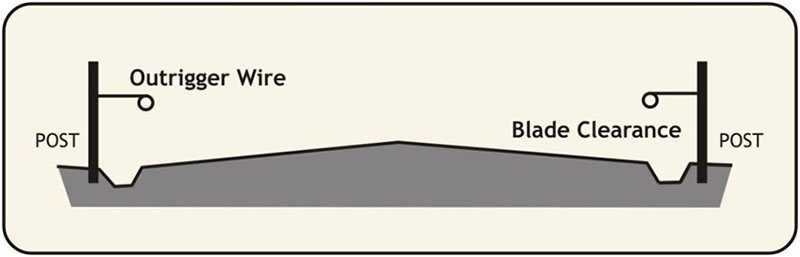

Position the fence so that the posts are on the paddock side but with an outrigger on the lane side of the drain.

Also, take care when moving cows along tracks which are bordered by hot wire fences.

This track fence keeps cows out of the drains while allowing access for cleaning.

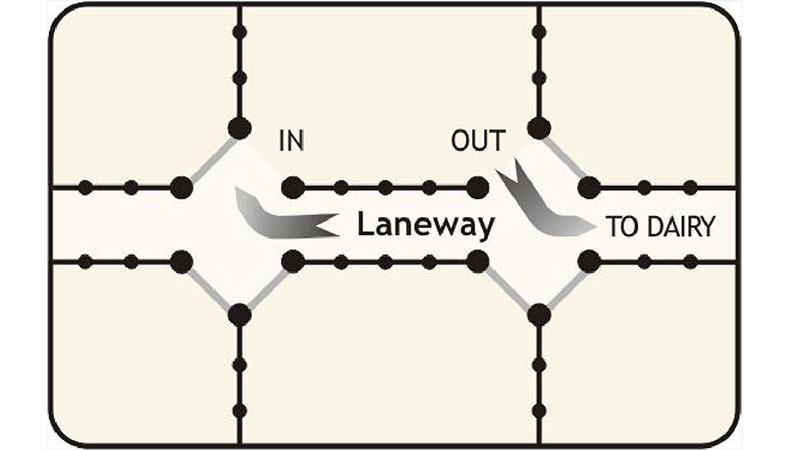

Access in and out of paddocks shouldn’t be narrower than the track or there will be bottlenecks. Put in double gates to avoid wear and tear and muddy areas.

Angled or offset gates improve cow flow, reduce track wear and tear and are easier to get machinery through.

V gates:

Open V gateways with access paths.

V Gateway.

Other ideas:

Make sure the track has a good surface and appropriate camber. Tracks can’t be too muddy, uneven or stony or have too much slope or it will affect cows’ ability and desire to use it.

Track surface camber

Track with good surface and appropriate camber.

Cows walking on side of track because camber is too steep.

Maintaining good tracks involves having a proactive program that ensures drainage is effective and surfaces are kept in top condition.

The maintenance programme has two focuses;

Muddy track caused by inappropriate surface and camber.

Minimise shaded areas to ensure tracks dry more rapidly.

When herding cows, an understanding of the way cows like to move is critical.

Three facts about cow movement;

Cows normally walk with their heads down looking at where they will place their feet.

Cows prefer little physical contact with others as they walk.

A cow that is left to move along quietly will seldom misplace a foot – even on a poor surface.

When a cow can’t place her feet safely she will slow down. This could be caused by:

Now’s the perfect time to check in, plan, and set up for a strong season. We’ve pulled together smart tips and tools to help you stay ahead all winter long.

Whether you prefer to read, listen, or download handy guides, we’ve got you covered with trusted tools to support your journey every step of the way.

Put our proven strategies and seasonal tools to work. Boost production, support animal health and watch your profits hum.

Tools that are backed by science, shaped by farmers and made for this season.

That’s Summer Smarts.

Autumn Smarts brings together the research-backed tools that build resilience and boost performance.