Plantain and Environment, Johan and Kylie van Ras (Te Puninga)

8 min read

This page provides a real-life example of how plantain is used in a dairy farm system and its environmental benefits. Johan and Kylie van Ras own and operate Waiorongomai Valley Farm, a 66 effective hectare dairy farm north-east of Hamilton. They have a keen environmental focus, having used plantain for several years, as well as retiring four hectares of unproductive land, developing it into what is now a thriving wetland. Johan and Kylie are also mindful of their bottom line and this page looks at the link between the operating profit and environmental footprint of Waiorongomai Valley Farm and how that compares with other dairy farms in the Waikato region.

Being environmental stewards is important for Johan and Kylie van Ras. Understanding the impacts of their actions on the health of the environment drives their decision making. The thriving biodiversity on Waiorongomai Valley Farm is a testament to the hard work Johan and Kylie put in to caring for the environment while running a profitable business.

The van Ras’s have been using plantain in their farm system for several years, knowing that it is the right thing to do. They tried plantain years before it hit the spotlight as a nitrogen mitigation tool.

I gave it a go in my mag spreader, using chicory and plantain, and the plantain hung around, so I thought here we go!

Johan van Ras

Farm owner

It wasn’t until sometime later they heard about the nitrogen loss benefits of using Ecotain environmental plantain. When Johan and Kylie were approached to become a partner farm in the Plantain Potency and Practice programme they agreed, knowing it would be a great opportunity to learn from other farmers who have had success using plantain and to connect with other like-minded farmers. As a partner farm, Waiorongomai Valley Farm will continue to be monitored until 2027.

After adjusting their methods of incorporating plantain and finding success, Johan and Kylie now have plantain present across 10% of their farm. While increasing the content to 20% would drop their N-loss figure below 20 kg N/ha/year, Johan and Kylie are happy with the 10% content across the farm that they have achieved.

Johan and Kylie van Ras own and operate Waiorongomai Valley Farm, north-east of Hamilton. Their milking platform is 66 effective hectares, with 4 ha of unproductive land developed into a thriving wetland area that is now attracting a range of native species.

Farm size (effective)

66 ha

Soil class

Allophanic & Gley soils (well to poorly drained)

Topography

Flat

Annual rainfall

1,065 mm/year

Average annual temp

14.5 degrees celsius

Herd size and breed

216 Friesian-cross

Stocking rate

3.3 cows/effective ha

Milksolids production (four-year average) per cow

462 kg MS/cow

Milksolids production (four-year average) per hactare

1,488 kg MS/ha

Farm system class

System 3

Purchased feed

~200 t PKE & 10-15 t DM other (e.g., silage, brewers grains)

We’re doing it because it’s the right thing to do. We don’t have any restrictions or rules to meet, but I sleep easier at night knowing our nitrogen leaching is low.

Johan van Ras

Farm owner

Modelling for the van Ras’s farm showed that by incorporating plantain at 20% across 60 ha of their 66-ha milking platform, it enabled them to reduce their N-loss by 24%, with only a 1% reduction in operating profit.

Two scenarios were modelled for Waiorongomai Valley Farm to reduce N-loss. The base farm is modelled without the use of plantain.

Scenario 1: Plantain

Scenario 2: Stacked mitigations

The impact of these scenarios on a range of metrics, including nitrogen leached and operating profit are shown in the table below. To achieve a similar level of N-loss as Scenario 1 (using plantain), Scenario 2 required stacking a number of mitigations together, which had a much greater impact on operating profit.

| Base (2022/23 season) | Scenario 1 (Plantain) | Scenario 2 (Stacked mitigations) | |

| Production (kg MS/year) | 99,948 | 99,948 | 97,398 |

| Stocking rate (cows/ha) | 3.3 | 3.3 | 3.3 |

| N fertiliser to pasture (kg/ha/year) | 130 | 130 | 111 |

| Pasture conserved (t DM/year) | 28 | 28 | 28 |

| Total N loss (kg N/year) | 1,983 | 1,514 | 1,741 |

| N leached (kg/ha/year) | 26 | 23 | 23 |

| N surplus (kg/ha/year) | 199 | 197 | 184 |

| Purchased N surplus (kg/ha/year) | 93 | 80 | 74 |

| Operating profit ($/ha)1 | $8,229 | $8,135 (-1.1%) | $7,913 (-3.8%) |

| Methane (t CO2 eq./ha) | 10.15 | 10.15 | 9.86 |

| Nitrous oxide (t CO2 eq./ha | 2.64 | 2.56 | 2.52 |

1Modelled in Farmax, based on DairyBase data.

Following their victory with establishing plantain using their mag spreader, the van Ras’s tried direct drilling plantain on their farm. However, this method of establishment wasn’t always successful, and it was through talking to another local farmer, that Johan and Kylie learnt about broadcasting the seed with fertiliser.

“We have an old oscillating Vicon spinner which we use behind the tractor,” says Johan. Using prill coated Ecotain seed, Johan broadcasts 8 kg seed (4 kg bare seed equivalent) per hectare mixed with serpentine super fertiliser. “That was an old trick my dad taught me, that serpentine super isn’t as harsh on the seed.”

Johan aims to broadcast plantain across a third of the farm every spring. While he acknowledges he doesn’t always do a third in reality, this method has allowed the van Ras’s to achieve a good plantain content across the farm.

Waiorongomai Valley Farm has a few problem weeds, particularly dock, buttercup and yellow bristle grass. Because of these weeds and the limited herbicide options that are safe for use on plantain, the van Ras’s don’t include plantain in their new pasture mixes. This allows them to have a wider range of herbicides to select from to control the weeds in newly establishing pastures. As soon as the withholding period has passed after spraying, Johan broadcasts the plantain seed on to these new pastures.

The actions all add up. Plantain might not be a silver bullet, but it’s certainly a tool.

Johan van Ras

Farm owner

Johan and Kylie won the Waikato Ballance Farm Environmental Awards in 2021, and it’s not hard to see why. The van Ras’s are passionate about protecting the environment and encouraging thriving, biodiverse habitats on their farm.

After arriving on the farm 12 years ago, Johan and Kylie noticed an area down the back of the farm that was always wet and poor producing. Over the next ten years and with some support from the Waikato Regional Council and the One Billion Trees Fund, the van Ras’s developed a thriving wetland area. They are now focusing on attracting the globally endangered matuku-hūrepo (Australasian bittern) bird to the wetland.

As well as their wetland, Johan and Kylie initiated the planting of 4 km of the Te Puninga waterway, which runs through their farm. Seeing the success of the CAREX work in Canterbury, the van Ras’s engaged with their local council and have planted Carex plants along the edges of one of the two waterways running through Waiorongomai Valley Farm.

These plants provide shade and reduce the water temperature, while also holding the banks of the waterway together and providing habitat for freshwater species living in the stream. The van Ras’s are using syringes from Wilderlab to measure the eDNA in the Carex-planted waterway and the unplanted waterway to identify the differences in species living in and around the two.

Alongside caring for their waterways, Johan and Kylie have also made a big difference to their bottom line by using technology to inform the placement of their fertiliser and effluent.

“There are massive efficiency gains by putting your fertiliser and effluent in the right place, at the right time,” says Johan, reflecting on everything they do to care for their environment. The accuracy GPS spreading used by the van Ras’s has the ability to geo-fence high nutrient risk areas, meaning that fertiliser won’t be spread there. Not only is this good for the environment, but reduces money spent on fertiliser too.

Johan and Kylie also pay particular attention to their farm effluent, using flow meters and GPS for spreading. Regular effluent sampling provides them with the nutrient content of the effluent, including the nitrogen, phosphorus and potassium levels. This allows them to use Overseer more accurately by moving beyond the standard Overseer assumptions of effluent nutrient content. This precision ensures that their decisions around nutrient management and farming practices align more closely with the actual conditions on their land, enhancing efficiency and environmental stewardship.

Remaining profitable is essential for farmers when meeting their environmental obligations.

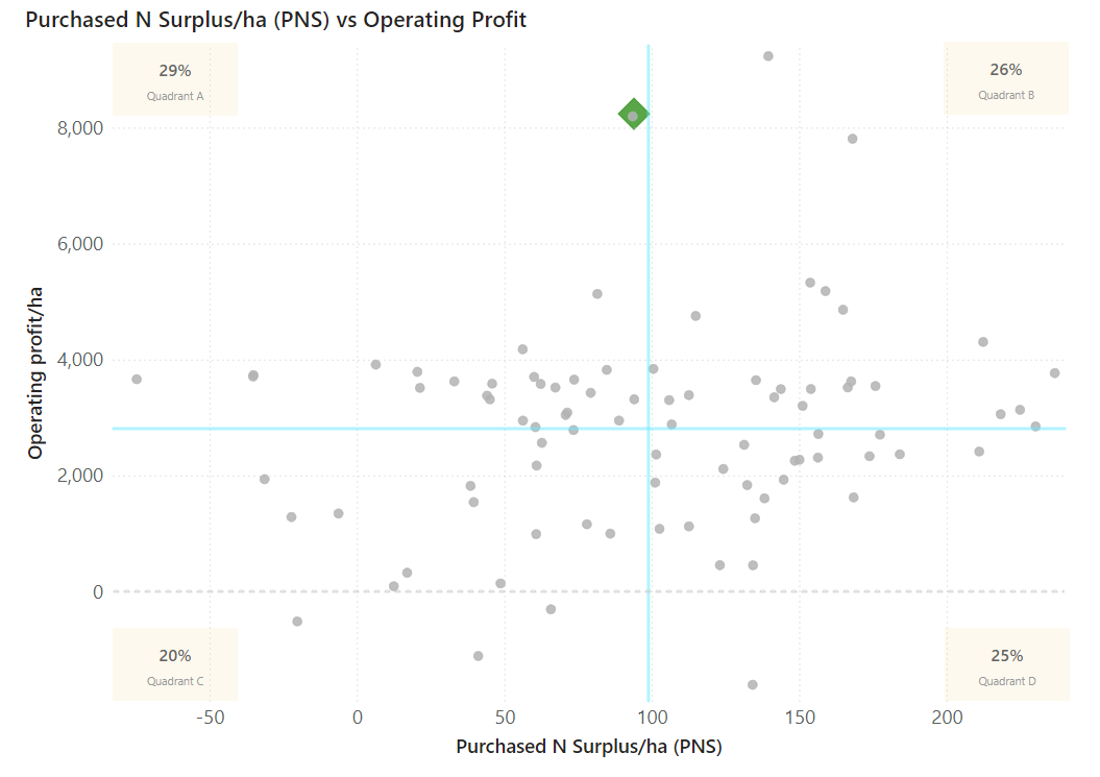

Purchased nitrogen surplus (PNS) is a measure that shows how efficiently a farm is turning imported nitrogen (from feed and fertiliser) into milk. The graph above shows the operating profit and purchased nitrogen surplus for Waikato DairyBase farmers for the 2022/23 season. The blue lines on the graph illustrate the intersection between profit and environmental footprint, showing where the average of the farms sit. The van Ras’s (indicated by the green diamond) had a higher-than-average operating profit and slightly below average purchased nitrogen surplus compared with other dairy farms in the Waikato region.

Data for Waikato dairy farms supplied anonymously from DairyBase Benchmarking.

While a high purchased nitrogen surplus can mean that a farm is at more risk of losing nitrogen to the environment, the method of calculating purchased nitrogen surplus does not consider nitrogen loss mitigations that a farmer may use. Johan and Kylie use a number of these mitigations such as plantain, tactical fertiliser and effluent placement and developing the wetland, meaning their actual nitrogen loss is a lot lower than their purchased nitrogen surplus might suggest.

To pull their purchased nitrogen surplus down further, Johan and Kylie could consider reducing the amount of imported feed they use or importing feeds with lower protein content, although it is important that this is balanced with the impact it would have on their milk production and operating profit.

When compared with other Waikato dairy farms in the 2022/23 season:

Data for Waikato dairy farms supplied anonymously from DairyBase.

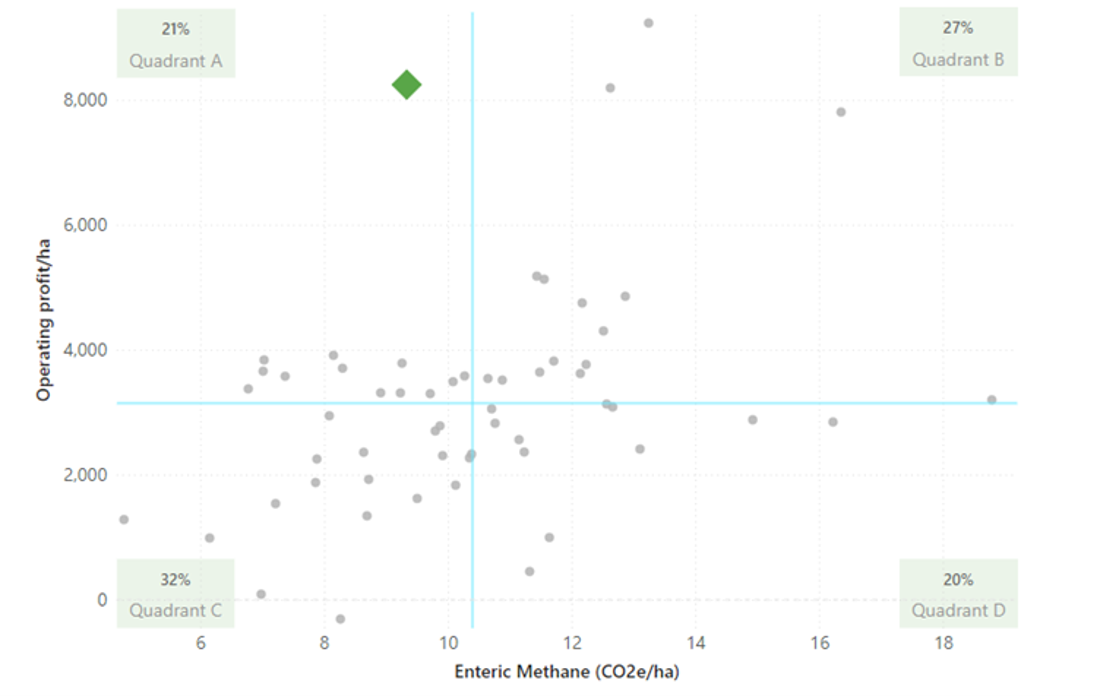

Enteric methane is closely linked to feed eaten, and there is a lot of methane research underway in NZ, including at DairyNZ, to look at what can be done to reduce enteric methane production, such as using alternative feeds or methane inhibitors.

Reducing methane researchOur guests on this episode are Morrinsville farmer Johan van Ras, planting professional Antony Snodgrass, and DairyNZ’s Aslan Wright-Stow, Senior Manager – Environment. Hear their perspectives on how to successfully undertake a planting project on the farm, including some common mistakes to avoid, tips on prep and maintenance, what we can learn from science and research, and what benefits (some unexpected) you’re likely to see.

Now’s the perfect time to check in, plan, and set up for a strong season. We’ve pulled together smart tips and tools to help you stay ahead all winter long.

Whether you prefer to read, listen, or download handy guides, we’ve got you covered with trusted tools to support your journey every step of the way.

Put our proven strategies and seasonal tools to work. Boost production, support animal health and watch your profits hum.

Tools that are backed by science, shaped by farmers and made for this season.

That’s Summer Smarts.

Autumn Smarts brings together the research-backed tools that build resilience and boost performance.